Needles, needles, needles, at Madeira we like to talk about needles a lot because the decision of which needle to use is crucial to the embroidery process. Natalie Greetham, marketing manager at Madeira UK, provides the lowdown on needles.

Needles, needles, needles, at Madeira we like to talk about needles a lot because the decision of which needle to use is crucial to the embroidery process. Natalie Greetham, marketing manager at Madeira UK, provides the lowdown on needles.

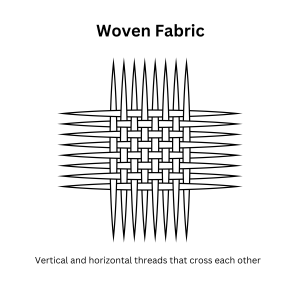

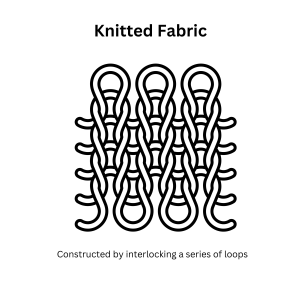

To consistently produce good quality embroideries the type of fabric, stabiliser, thread, and stitch density of the design you will be working with are major factors to consider as they all affect the size and point of the needle you should choose.

Different fabrics and applications require specific types of needles, and it can be a minefield to select the correct ones. Let’s look at some of the various needle types and when to use them, the letters refer to the needle tip:

- RG = for tightly woven textiles, use a standard sharp point.

- SES/ FFG = the rounded tip of this light ballpoint is designed to separate through the weave of fabrics such as fleece, knits, and polo shirts.

- SUK = for loose-knit textiles that stretch, use a medium ballpoint.

- GEBEDUR is a trademark and registered brand name of needle manufacturer Groz Beckert. Made from wear-resistant titanium and designed to last up to five times longer than standard needles.

- SAN1 = Special Application Needles, the extra strong sharp point makes them ideal for caps, martial arts belts, and thick leather. The strengthened blade increases needle stability and reduces deflection and breakage.

- SAN8 = extra strong ballpoint needles with a larger eye for specific textured metallic threads such as Madeira’s Supertwist. The larger eye makes it easier to thread and allows the thread to glide more freely.

The next thing to consider is thread weight as this will determine the size of the needle to use. For example, the recommended needle size to use with industry-standard 40-weight thread is either 65/9 or 75/11. The smaller the hole the less risk there is of damaging the fabric of the garment and the neater the finished embroidery results will be.

Top tips to remember:

- For needles, the higher the number the larger the needle.

- For thread, the higher the number the finer the thread.

Industrial embroidery machines require needles that are round at the top, the part that fits into the machine, and have a grove down the centre which should always be fitted facing the front. Domestic machines or semi-industrial machines have a flat back which should be fitted facing the back of the machine.

Industrial embroidery machines require needles that are round at the top, the part that fits into the machine, and have a grove down the centre which should always be fitted facing the front. Domestic machines or semi-industrial machines have a flat back which should be fitted facing the back of the machine.

How often should you change your needles? To the naked eye, your needles may look fine, but this might not be the case. Excessive abrasion can damage needles and cause them to go blunt. Ideally, needles should be changed after approximately eight hours of work. As part of your machine maintenance routine, we recommend setting a schedule for replacing needles e.g. changing one needle per head each week. By changing needles regularly, you can avoid unnecessary downtime caused by common embroidery problems such as thread breaks, looping stitches, puckering, fabric damage, birdnesting and skipped or uneven stitches. When problems occur, needles are often overlooked and only replaced when they break but this is a false economy as they are a vital component yet relatively inexpensive.

Understanding the various needle types and their functions will help you embroider confidently whatever the application, who would have thought that something so small could have such a big impact on your embroidery results?

Printwear & Promotion The Total Promotional Package

Printwear & Promotion The Total Promotional Package