This year will be an exciting one for T shirt printing. Two companies familiar to P&P readers: Resolute DTG and EXILE Technologies, are working on a joint venture that combines their vast experience within the textile printing sector.

For over a year the two companies have been working on the MiniFB Project (FB = flatbed), a groundbreaking flatbed design allowing multiple print applications from a new, affordable three axis ink jet printing system. Similar to the arrangement when car manufacturers share chassis designs, the MiniFB Project will spawn a range of exciting new direct to substrate products for different sectors of the printing industry. The two manufacturers have shared knowledge and expertise gained over 20+ years. Now they are poised to turn the flatbed printing industry on its head, as they bring a unique range of machines to market with an unheard of sub £10,000 price tag.

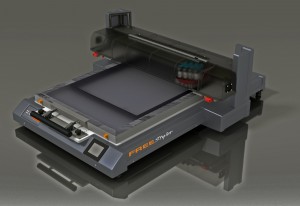

First to go on sale will be the FREEStyler Computer to Screen system from EXILE which will be officially launched at P&P LIVE! 2016. Resolute will also offer a sneak preview of its first MiniFB based product – the R-Jet CS, which gets its first public viewing at the show.

R-Jet CS Multi Function Fabric Printer

The R-Jet CS is multi function device. Flatbed dye sublimation for transfer or direct to garment that can also print onto cotton. Fitted with a vacuum bed for transfers and pin registration T shirt platens, the R-Jet CS brings a completely new concept to the dye sublimation and cotton decoration industry. No print heads to change, no capping station to replace and no ink tubes results in as close to zero maintenance you can get.

FREEStyler Direct to Screen

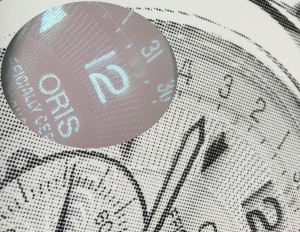

EXILE’s FREEStyler DTS is the world’s first truly affordable computer to screen solution. Using low cost disposable printer cartridges with specially developed UV-Block Black Ink, the FREEStyler frees screen printers from having to use costly and time consuming film positives. Instead the image or stencil is digitally printed onto a normal emulsion coated screen. After imaging, the screen is ready for immediate exposure without the need for a glass or vacuum. Then the water-based ink washes off quickly and easily with the unexposed emulsion.

FREEStyler’s simple design ensures it is virtually maintenance free and very easy to use. FREEStyler is configurable with one, two or four disposable print cartridges that can be swapped out in seconds. Each cartridge is capable of producing 50+ typical T shirt images, translating to production and running costs of under £1 per screen.

FREEStyler supports Screen frames up to 36x25in with 24x20in maximum imaging area despite its compact tabletop profile.

FREEStyler incorporates ScreenMaker RIP – a special version of the best selling FilmMaker RIP from CADLink. ScreenMaker features selectable print modes for fast printing of solid blacks in only two to three minutes and HQ (High Quality) modes for halftone images. Even in HQ modes the FREEStyler images six to 12 separations per hour.

ScreenMaker supports optional in RIP separations and allows direct printing from your favorite graphics applications as well as drag and drop output. Images are digitally positioned relative to the screen frame via ScreenMaker’s template function. Registration accuracy is mechanically guaranteed via FREEStyler’s unique tri-lock based screen clamping system, which is compatible with standard screen frames and also accommodates pin registration systems, such as MHM or Newman Roller frames.

As EXILE’s managing director Mark Evans explained: “For most textile printers the idea of computer to screen is very appealing but the financial reality is that, up to now, it has been too expensive to justify the ROI. FREEStyler is aimed at screen printers making maybe only 20 to 30 screens per day, probably using ink jet film positives. FREEStyler eliminates the hassle of working with film. When you see the FREEStyler in action the argument is utterly compelling. Why add the extra step of making a film positive when a direct image or stencil is much quicker to produce and easier to register on press?”

EXILE Technologies manufactures thermal imagesetters for screen printing and the SPYDER II DTS system, which is the leading computer to screen solution for textile and transfer screen printing in Europe.

Resolute DTG manufactures the R-Jet series of direct to garment printers including the best-selling R-Jet 5.

01582 573980

sales@exiletech.co.uk

www.exiletech.co.uk

01246 202686

info@resoluteink.co.uk

www.resolutedtg.com

Printwear & Promotion The Total Promotional Package

Printwear & Promotion The Total Promotional Package