This month Jas Purba, managing director of ETC Supplies, discusses tension and how to overcome this all too familiar embroidery problem.

I am not referring to the mental type of tension but your thread tension. The single biggest problem we encounter in the embroidery industry is poor thread tension settings.

It never ceases to amaze me how both small and large companies over look this most important embroidery machine setting. Embroiderers are very quick to blame embroidery thread as not running well on their machine, causing thread breaks, but this is only due to poor thread tension settings and worn out eyes of the needle.

Generally in the UK embroidery thread tensions are set to high. One of the most disturbing issues is the fact that embroiderers do not adjust thread tensions for different thickness of fabric. This observation is re-enforced by the fact that embroiderers use very strong poly/cotton under thread due to under thread breaking with the strong pull of the top thread.

If the top thread tension was set lower, then they would not have to use such a strong under thread. You only have to understand the process that is involved between the top thread and under thread to achieve better thread settings.

What happens?

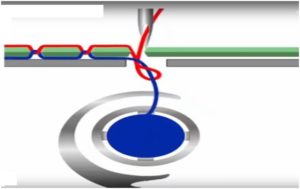

The needle brings the top thread down through the fabric and on the way back up it creates a loop.

The under thread is fed through the loop by the rotating hook to stop the top thread being pulled back up and this provides the knot.

The principle is just the same as tying a shoe lace. If you wear thick socks you will require a lower tension on your shoelace than if you were wearing thin socks. So why would you not apply this principle to your embroidery machine?

The principle is just the same as tying a shoe lace. If you wear thick socks you will require a lower tension on your shoelace than if you were wearing thin socks. So why would you not apply this principle to your embroidery machine?

Wilcom has produced a very informative chart that illustrates the balance between top and bottom thread tensions.

Next, embroiderers complain that the backing is not strong enough for them and use more layers, to stop the thread pulling through. The cause of this again is high tensions. We will talk about embroidery backings another day. You can easily see this problem when looking at the back of the embroidery. You will see the under thread is missing and only the top thread is visible on the underside.

Next, embroiderers complain that the backing is not strong enough for them and use more layers, to stop the thread pulling through. The cause of this again is high tensions. We will talk about embroidery backings another day. You can easily see this problem when looking at the back of the embroidery. You will see the under thread is missing and only the top thread is visible on the underside.

Embroiderers always complain about puckering. Again this is due to thread tension settings. If your thread tension was set lower the fabric would not be pulled during the embroidery process. One major thread brand, actually tells people that their thread stretches and does not break during embroidery. Well, if that happens, then just like a rubber band it will contract back to its original size and cause puckering.

If you look at your embroidery, this is especially noticeable on large stitch designs; the embroidery should be sitting on top of the fabric. But in many cases the embroidery is pulled into the fabric.

If you run your machine at very fast speeds you will have a higher tension setting. So again, to achieve better quality embroidery and less thread breaks run your machine at a moderate speed.

I would always recommend that you provide your staff with thread tension settings training from your machine engineer. This small cost will pay dividends in the long run. While you get this done, also ask him to check that your top thread is set up to run in the correct direction. This training will help you achieve better embroidery results.

Tension gauges for both top and bottom thread are available. But these are a guide only and you do not have a set tension for every different type of embroidery fabric. These are very goods tools for multi head machines so that if you set one head thread tension correctly, you can then use the same tension on the other heads.

A number of factors will influence your thread tension setting. Here are some points to look at.

- Type of needles and inserting them correctly. The manual will tell you the needle should be 10⁰ to the right, but this is impossible to judge so I suggest you put it in straight with the groove facing the front.

- Balance top and bottom thread tensions.

- Maintain tension springs and felt. Renew on a regular basis.

- Tension knobs, make sure these are in good condition and work properly. Over a period of time the thread will create a groove in the metal and this will prevent you adjusting the thread tension.

- Ask your machine engineer to provide you with basic knowledge.

- Thick and thin garments. Adjust your tensions accordingly.

- Machine speed. Find the optimum speed for your machine.

- Keeping bobbin cases clean and in good condition this will result in better tensions.

- Regular maintenance to keep your machine running smoothly.

Printwear & Promotion The Total Promotional Package

Printwear & Promotion The Total Promotional Package