At a DTG Breakthrough event Amaya Sales UK held back in July, the team incorporated into the day a question-and-answer session with experts from DTG manufacturers, garment manufacturers and the company’s own in-house experts. In this month’s article, Charlotte Darling, has gathered a selection of those questions taken from customers which were fired at the experts.

At a DTG Breakthrough event Amaya Sales UK held back in July, the team incorporated into the day a question-and-answer session with experts from DTG manufacturers, garment manufacturers and the company’s own in-house experts. In this month’s article, Charlotte Darling, has gathered a selection of those questions taken from customers which were fired at the experts.

Q. What trends are print on-demand companies seeing?

A. The larger DTG fulfiller companies are being approached by brands of all sizes, who are looking for a more sustainable solution to their fulfilment and supply chain model. When I say more sustainable, I’m not just talking in an environmental sense, but from the aspect of the amount of stock being held, the speed and availability of it and the reduction in wasted product that does not sell. These are the multiple benefits that print on-demand offers. Ultimately the trend will over time filtrate down through all levels of fulfilment whether industrial or mid-level.

Q. Why is everyone talking about DTF?

A. Well, it fixes a problem. It offers a multi-colour digital print of a reasonable quality, with more cost-effective consumables than other digital transfer processes on the market like white toner. It is weeded and will print onto multiple fabric types. The technology is not really new, direct screen transfers have been around for many years.

I do think it would be a mistake for any business to solely rely on this as the only way to decorate a garment. It’s just not the magic bullet – it can’t fade into black like DTG and screen print, the application on polyester is questionable and the transfer finish does not meet certain guidelines set out by some brands and end consumers. Lastly, the future of the transfer on a film carrier I believe is short lived from an environmental perspective.

Q. When is the right time to scale a DTG business?

A. If you are looking to expand and grow your DTG, print on-demand business I would look for two key indicators. The first is simple when your demand exceeds production on a regular basis. Secondly is based on cost per print. To attract larger volumes will require you to be more competitive with your digital print so there is a turning point when you will need to move to a more industrial system for the bulk ink feed cost benefits. Entry level DTG works great for B2C business, like your own brand for example, but if you want to move to B2B and attract bigger accounts you will need the right solution for cost per print.

Q. What drives DTG growth?

A. There are many factors that have driven DTG growth in the last seven years and the continued improvement in efficiency and speed of systems on the market, makes it the number one solution for sustainable print on-demand. Aside of this key factor, I would say the market is looking for supply chain efficiency, with localised production as near to the end consumer as possible. Small production runs and the need to print per order instead of mass production is driven by the end consumer and the growth of new sales channels like influencers on social media and different platforms.

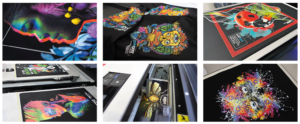

Q. Why someone would prefer DTG over other methods?

A. Direct to garment printing offers a digital solution, with unlimited colours and minimum set up. It’s generally compact in size so let’s many businesses offer print on-demand in-house. Another big advantage is colour accuracy for repeat and returning customers, and also how easy it is to offer different size prints within an order of different sized garments. I would also argue that with the right training in the operating software on the systems you can achieve better high-quality prints than with other print processes on the market. Due to the lack of set up time required, the cost per print is also usually lower, and competitive at all levels of business. Finally, it’s become an accepted decoration method by many brands, compared with say a transfer process, and very often it is the market that drives the demand.

Q. Is every organic cotton the same?

A. Organic cotton refers to naturally cultivated cotton without the use of any synthetic agricultural chemicals such as fertilisers or pesticides or transgenic technology. It can only be classed as organic cotton if certified by a ‘standard’ such as GOTS, OCS, NATURTEXTIL MN.

The biggest difference though is between organic and sustainable cotton. However, organic certification does not cover the additional issues of cultivation and farming practices which impact the environment and population, such as emissions, biodiversity and employee working conditions. Sustainable cotton refers to cotton production which takes these numerous impacts into consideration, with the aim of reducing negative impacts and supporting positive outcomes in an ideally holistic manner; this includes the entire cotton lifecycle such as the sustainable use of recycled cotton.

Q. Why is digital printing and on-demand fulfilment getting more and more important for textile brands?

A. Because of the supply chain disruption, which took place during the last two years, the trend clearly moved towards near shoring and a wider range of application which can be applied post fabric production. This is also reflected in the option to have virtual products, visual representations of designs on fabrics which can be offered to clients but do not exist before an actual order is placed. The whole philosophy of print what you sell, not sell what you print.

I hope you have learnt something new. If you have any further questions about DTG, technical or otherwise, we at Amaya will be happy to answer them for you.

Printwear & Promotion The Total Promotional Package

Printwear & Promotion The Total Promotional Package